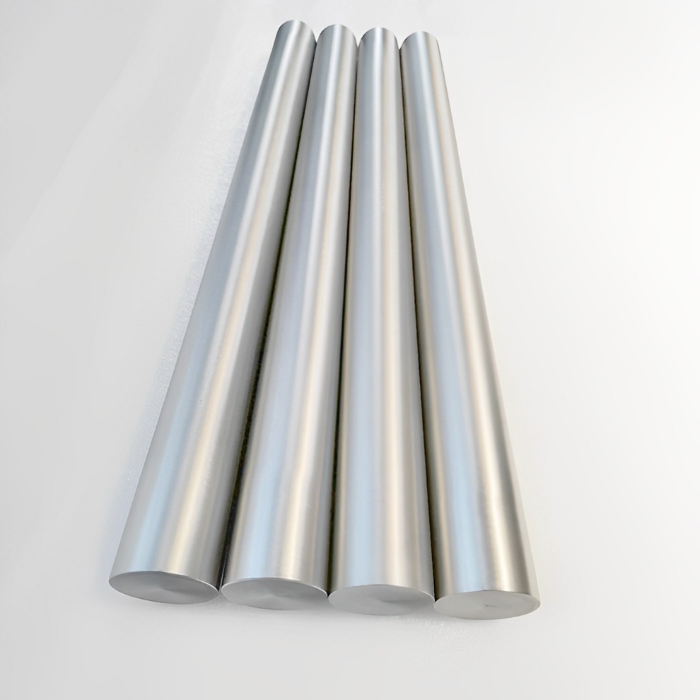

Ogo TZM Molybdenum Alloy Rod

Ụdị na nha

TZM Alloy rod nwekwara ike ịkpọ aha dị ka: TZM molybdenum alloy rod, titanium-zirconium-molybdenum alloy mkpanaka.

| Aha ihe | TZM Alloy Rod |

| Ihe onwunwe | TZM Molybdenum |

| Nkọwapụta | ASTM B387, Ụdị 364 |

| Nha | 4.0mm-100mm dayameta x <2000mm L |

| Usoro | Ịse, swaving |

| Elu | Black oxide, kemịkalụ ihicha, mechaa tụgharịa, na-egweri |

Anyị nwekwara ike ịnye akụkụ TZM Alloy machined kwa eserese.

Ngwakọta kemịkalụ nke TZM

Isi ihe: Ti: 0.4-0.55%, Zr: 0.06-0.12%, C: 0.01-0.04%

| Ndị ọzọ | O | Al | Fe | Mg | Ni | Si | N | Mo |

| Ọdịnaya (wt,%) | ≤0.03 | ≤0.01 | ≤0.002 | ≤0.002 | ≤0.002 | ≤0.002 | ≤0.002 | Bal. |

Uru nke TZM ma e jiri ya tụnyere molybdenum dị ọcha

- Ihe karịrị 1100ºC ike ndọtị dị ihe dị ka okpukpu abụọ karịa nke molybdenum na-adịghị ahụkebe

- Nguzogide na-akpụ akpụ ka mma

- Okpomọkụ recrystallisation dị elu

- Njirimara ịgbado ọkụ ka mma.

Atụmatụ

- Njupụta:≥10.05g/cm3.

- Ike ọdụdọ:≥735MPa.

- Ike mpụta:≥685MPa.

- Mgbatị:≥10%

- Isi ike:HV240-280.

Ngwa

TZM na-efu ihe dịka 25% karịa molybdenum dị ọcha ma na-efu naanị 5-10% karịa na igwe.Maka ngwa ike dị elu dị ka nozzles rọketi, ihe nrụpụta ọkụ arụrụ arụ, na ịnwụ anwụ, ọ nwere ike ịba oke ọnụ ahịa dị iche.

Dee ozi gị ebe a ziga anyị ya