Tungsten ọla kọpa Alloy Rods

Nkọwa

Achọpụtala tungsten ọla kọpa (CuW, WCu) dị ka ihe na-eme ka ọ bụrụ ihe na-eme ka ọ bụrụ ihe na-eguzogide ọgwụ na mkpochapu nke a na-ejikarị dị ka ọla kọpa tungsten electrodes na ngwa EDM machining na iguzogide ịgbado ọkụ, kọntaktị eletrik na ngwa voltaji dị elu, na ikpo ọkụ na ihe nkwakọ ngwaahịa eletrọn ndị ọzọ. na thermal ngwa.

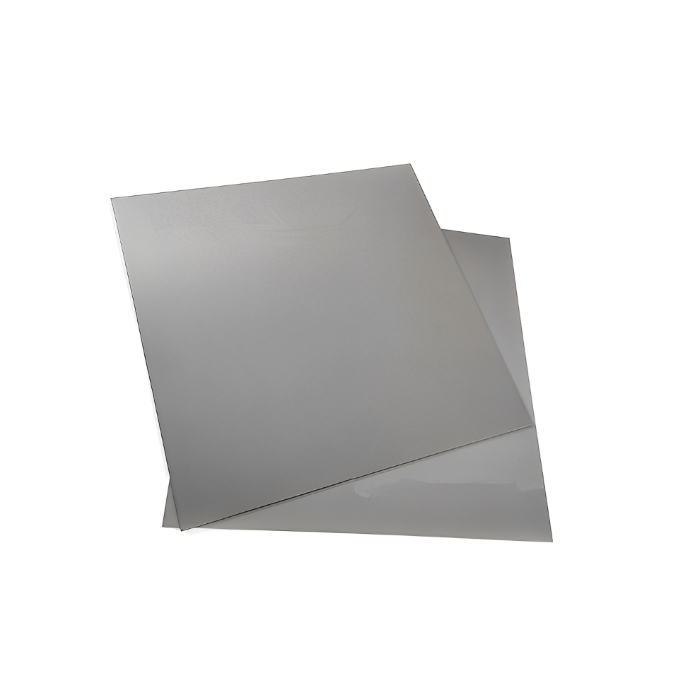

Oke tungsten/ọla a na-ahụkarị bụ WCu 70/30, WCu 75/25 na WCu 80/20.Ihe ndị ọzọ a na-emekarị gụnyere tungsten/ọla kọpa 50/50, 60/40, na 90/10.Ogo nke ihe ndị dịnụ sitere na Cu 50 wt.% ruo Cu 90 wt.%.Ngwa ngwaahịa ọla kọpa tungsten anyị gụnyere mkpanaka tungsten ọla kọpa, foil, mpempe akwụkwọ, efere, tube, mkpanaka ọla kọpa tungsten, na akụkụ igwe.

Njirimara

| Ihe mejupụtara | Njupụta | Igwe ọkụ eletrik | CTE | Nrụpụta okpomọkụ | Isi ike | Okpomọkụ akọwapụtara |

| g/cm³ | IACS % Min. | 10-6K-1 | W/m · K-1 | HRB Min. | J/g · K | |

| WC 50/50 | 12.2 | 66.1 | 12.5 | 310 | 81 | 0,259 |

| WC 60/40 | 13.7 | 55.2 | 11.8 | 280 | 87 | 0,230 |

| WC 70/30 | 14.0 | 52.1 | 9.1 | 230 | 95 | 0.209 |

| WC 75/25 | 14.8 | 45.2 | 8.2 | 220 | 99 | 0.196 |

| WC 80/20 | 15.6 | 43 | 7.5 | 200 | 102 | 0.183 |

| WC 85/15 | 16.4 | 37.4 | 7.0 | 190 | 103 | 0.171 |

| WC 90/10 | 16.75 | 32.5 | 6.4 | 180 | 107 | 0,158 |

Atụmatụ

N'oge a na-emepụta ọla kọpa tungsten alloy, a na-agbanye tungsten dị ọcha dị elu, na-agbanye ya wee banye na ọla kọpa na-enweghị oxygen na-abanye ya mgbe usoro nchikota ahụ gasịrị.Ngwakọta ọla kọpa tungsten jikọtara ọnụ na-enye microstructure dị n'otu na ọkwa dị ala nke porosity.Nchikota nke ọla kọpa na njupụta dị elu nke tungsten, isi ike na ebe mgbaze dị elu na-emepụta ihe mejupụtara nwere ọtụtụ ihe ndị bụ isi nke ihe abụọ ahụ.Tungsten-infiltrated ọla kọpa na-anya isi ihe ndị dị ka nnukwu iguzogide oke okpomọkụ na arc-erosion, ezigbo ọkụ na ọkụ eletrik na obere CTE (ọnụọgụ nke thermal).

Ngwongwo anụ ahụ na nke arụ ọrụ na ebe mgbaze nke tungsten ọla kọpa ga-enwe mmetụta dị mma ma ọ bụ nke ọzọ site n'ịgbanwe ọnụọgụ ọla kọpa tungsten dị na ngwakọta.Dịka ọmụmaatụ, ka ọdịnaya ọla kọpa na-eji nwayọọ nwayọọ na-abawanye, ọkụ eletrik na ọkụ ọkụ na mgbasawanye ọkụ na-egosipụta àgwà nke ịdị ike karị.Otú ọ dị, njupụta, nguzogide eletriki, ike siri ike na ike ga-ebelata mgbe ejiri obere ọla kọpa tinye ya.Ya mere, ihe mejupụtara kemịkalụ kwesịrị ekwesị bụ ihe kachasị mkpa mgbe ị na-atụle ọla kọpa tungsten maka mkpa ngwa ngwa.

Mgbasa ọkụ dị ala

High thermal na eletriki conductivity

Nnukwu arc na-eguzogide

Oriri dị ala

Ngwa

Ojiji Tungsten ọla kọpa (W-Cu) abawanyela nke ọma n'ọtụtụ mpaghara na ngwa n'ihi akụrụngwa ya dị iche iche na akụrụngwa thermophysical.Ihe ọla kọpa Tungsten na-egosipụta arụmọrụ dị elu n'akụkụ nke ike, ike, omume, okpomọkụ dị elu, na nguzogide arc.Ejirila ya nke ọma maka imepụta kọntaktị eletrik, ndị na-ekpo ọkụ ọkụ na ndị na-ekesa, electrodes EDM na-anwụ anwụ na nsị injection mmanụ.